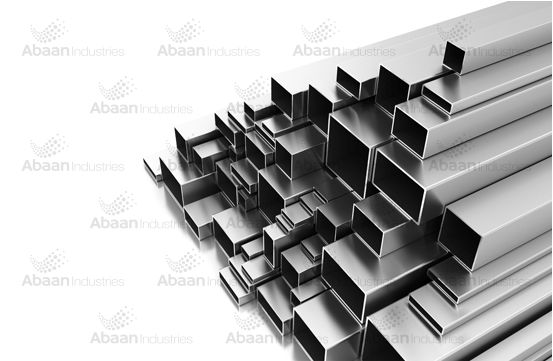

SQUARE PIPES / BOX SECTIONS

Mild Steel Electric Resistance Welded (ERW) Pipes are manufactured from Hot Rolled Coils / Slits.

Hot Rolled Steel Coils/Plates are roll formed into circular pipes and processed into electric resistance welded (ERW) pipes according to different specifications (OD, thickness, and material). Most ERW pipes are circular, but some can be processed to be angulated into different shapes, including a Square & Rectangular form, but ERW pipes are categorized into CHS (Circular Hollow Sections), SHS (Square Hollow Sections), RHS (Rectangular Hollow Sections) type depending on the manufacturing method.

From Base materials for Construction to Infrastructure, they are also used extensively in various industries such as Engineering Industries.

GI/GP SQUARE & RECTANGULAR HOLLOW SECTIONS

Galvanized Steel are those Steel that has been Covered with a Layer of Zinc Metal. During Galvanizing, Steel is Immersed in a Molten Zinc Bath, Ensuring a Tough, Uniform Barrier Coating.

Zinc's Natural Corrosion Resistance Provides Long-term Protection, even in Outdoor Environments. Apart from Preventing Water Corrosion, it is Equally Effective in Dry, Indoor Environments. GI/GP Pipes and Tubes are Mostly used in Structural Applications.

GRADES

ASTM A 500 IS 4923 YST 210 YST 240 YST 310 YST 355

PRODUCT SPECIFICATIONS

Sizes (SHS - BxB) : 25x25mm to 250x250mm

Thickness : 2mm to 10mm

Sizes (RHS - DxB) : 50x25mm to 300x200mm

Thickness : 2mm to 10mm

Length : All Standard Sizes are Readily Available. Customised Sizes can be Supplied as per Clients Requirements.

FEATURES

Excellent Wear Resistance

Goods Corrosion Resistance

Low Friction

Fine Quality

Extended Life of Parts

High Strength

Rust Proof

Tough Surface

Accurate Thickness

Durable Finish

Easy to Use

Low Maintenance

Perfect Bonding

APPLICATIONS

Furniture Industries Cabins Bus Stands Columns & Purlins Automatic Chasis Industrial Sheds Cranes Material Storage Racks Frame Work Pallets Guard Rails Staircases etc...

If You Need Any Steel Product Solution ... We Are Available For You

Abaan Industries has Grown Positively through the years because of our Customers Co-operations, Trust and Support.We Always Intend to Provide the Best Quality of Products & Service to our Customers in the Industry.